2025 Guide: How to Choose the Best Tray Sealer for Your Business Needs

In the world of food packaging, efficiency and quality are paramount, and one of the key players in achieving these goals is the tray sealer. As businesses strive to enhance their operational workflows while safeguarding product integrity, choosing the right tray sealer has become increasingly critical. A proper selection not only impacts production speed but also influences the longevity and freshness of the packaged goods.

This guide will delve into the essential factors to consider when selecting the best tray sealer tailored to your specific business needs. From understanding the various types of tray sealers available in the market to evaluating features such as sealing technology and automation capabilities, we aim to provide comprehensive insights that cater to diverse operational requirements. By the end of this guide, you will be equipped with the knowledge necessary to make an informed decision and invest in a tray sealer that aligns with your production goals and enhances overall efficiency.

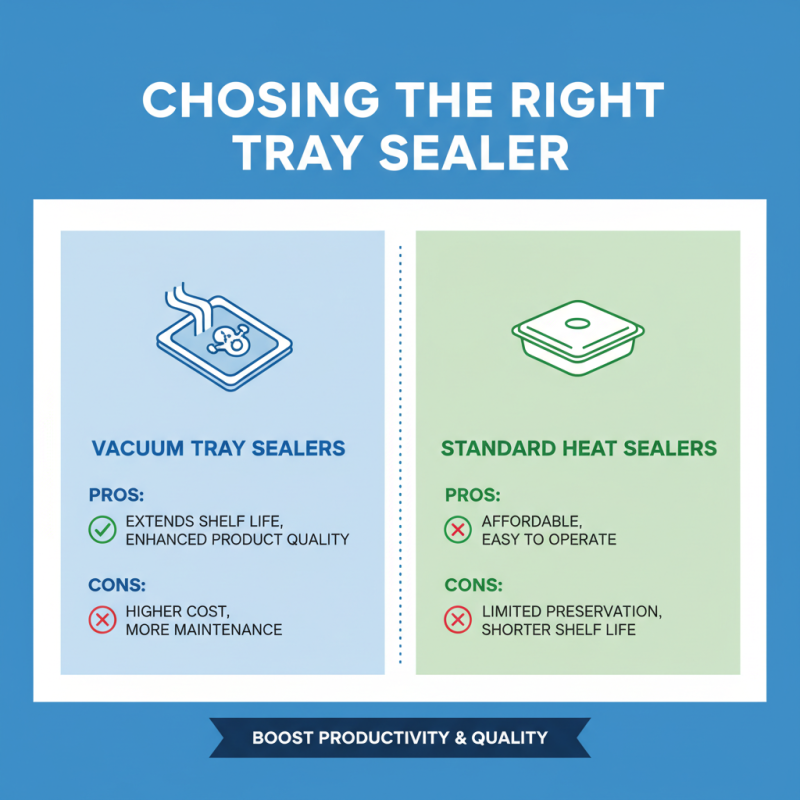

Understanding Different Types of Tray Sealers: Pros and Cons

When selecting the right tray sealer for your business, understanding the different types available is crucial. Each type comes with its own set of pros and cons, which can significantly impact productivity and product quality. For example, vacuum tray sealers are excellent for extending shelf life by removing air, but they may require more maintenance and have a higher initial cost. On the other hand, standard heat sealers are generally more affordable and easier to operate, making them a popular choice for smaller operations. However, they may not provide the same level of food preservation.

**Tip:** Consider the volume of production and the specific requirements of your products when choosing a tray sealer. If you are dealing with perishable items that require long shelf life, investing in a vacuum sealer could be beneficial despite the higher costs. Conversely, if your focus is on speed and efficiency with less tamper resistance, a basic heat sealer might serve your needs just fine.

Another option is modified atmosphere packaging (MAP) sealers, which replace the air with a gas mix to slow down deterioration. While these sealers can significantly enhance product longevity and freshness, they tend to be more complex and can require specialized training. Always weigh the initial investment against potential long-term savings in spoilage and waste.

**Tip:** Analyze your target market’s preferences and the type of products you plan to sell. This assessment will guide you in choosing a sealer that not only meets your current needs but also allows for future growth.

Key Factors Influencing Tray Sealer Performance for Your Business

When selecting a tray sealer for your business needs, it’s crucial to focus on several key factors that can significantly influence its performance. First, consider the sealing technology employed by the machine. Options such as vacuum sealing, modified atmosphere packaging, and heat sealing each offer unique benefits depending on the nature of your products. Understanding the specific requirements of your items, such as shelf life and perishability, can help you determine which technology is best suited for your operations.

Another critical factor is the machine's throughput capacity. Businesses with high production demands should assess the tray sealer’s speed and efficiency to ensure it can handle the volume required. Features like automation and ease of operation also play a vital role in minimizing labor costs and improving productivity. Additionally, the overall design and flexibility of the sealer, including its ability to accommodate different tray sizes and materials, can impact how well it meets your evolving business needs. Investing time in evaluating these aspects ensures that the tray sealer you choose aligns with both your current and future operational requirements.

2025 Guide: How to Choose the Best Tray Sealer for Your Business Needs

| Feature | Importance Level | Typical Range | Remarks |

|---|---|---|---|

| Sealing Speed | High | 10-30 packs/min | Affects production efficiency |

| Sealing Quality | Critical | 99% seal integrity | Prevents contamination |

| Size Compatibility | Medium | Customizable | Flexibility for various products |

| Material Compatibility | High | Plastic, Aluminum | Ensures versatile use |

| Ease of Operation | Medium | User-friendly design | Affects training time |

| Maintenance Requirements | High | Regular intervals | Ensures longevity |

| Energy Efficiency | Medium | Low to High consumption | Impact on operational costs |

| Price Range | Critical | $5,000 - $50,000 | Budget consideration |

Evaluating Production Capacity: Choosing the Right Speed and Volume

When evaluating production capacity for tray sealers, understanding the right speed and volume is crucial for optimizing operational efficiency. According to industry reports, the average output of a mid-range tray sealer is about 20 to 40 trays per minute, which can significantly impact your overall productivity. Businesses that demand higher volume should consider equipment capable of achieving speeds of up to 100 trays per minute. However, it's essential to match the speed with your current production needs; overestimating can lead to operational bottlenecks and increased maintenance costs.

In addition to speed, assessing the volume of product that will be sealed is imperative. The Food Processing Industry reported that around 70% of manufacturers require a versatile solution that can handle varying tray sizes and materials. A tray sealer must be adaptable not only to the type of food product being packaged but also to seasonal fluctuations in demand. Data shows that companies experiencing a 20% increase in product demand during peak seasons benefited significantly from investing in automatic tray sealers that can easily handle larger volumes while maintaining the quality of seal integrity. Balancing these factors ensures that the equipment selected serves the business needs effectively, aligning production capabilities with market demands.

This bar chart illustrates the production capacity of tray sealers categorized by their speed settings. Depending on your business needs, selecting a sealer with the appropriate speed can significantly impact your efficiency and output.

Cost vs. Quality: Analyzing the Total Cost of Ownership for Tray Sealers

When selecting a tray sealer for your business, understanding the balance between cost and quality is essential, as it directly impacts your total cost of ownership (TCO). The initial price of the machine may seem like the most critical factor, but a deeper analysis reveals that long-term expenses, including maintenance, energy consumption, and training, play a significant role in determining the overall investment. High-quality machines with advanced features may come with a higher upfront cost, but they often lead to lower operating costs over time due to their durability and efficiency.

Moreover, it’s important to consider how the chosen sealer affects your production process and product quality. A reliable tray sealer can enhance operational efficiency, reduce waste, and improve product shelf life, all of which contribute to long-term savings. Therefore, when analyzing the TCO, businesses must evaluate how the equipment's reliability and performance can mitigate potential losses associated with downtime, product spoilage, or poor sealing quality. Ultimately, investing in a quality machine could lead to greater profitability, making it a worthwhile consideration against initial cost constraints.

Future Trends in Tray Sealing Technology: Innovation and Sustainability

The tray sealing technology is poised for transformative advancements by 2025, focusing on innovation and sustainability. As the global market for tray sealing machinery is expected to reach approximately $3 billion by 2025, businesses must adapt to these trends to remain competitive. According to a recent industry report, sustainable packaging solutions are becoming pivotal, with more than 70% of consumers expressing a preference for environmentally friendly products. This shift necessitates the integration of biodegradable and recyclable materials in tray sealing processes, thereby reducing plastic waste.

One of the key innovations in tray sealing is the adoption of smart technologies, which enhance operational efficiency and product quality. Automation and AI-driven systems allow for better quality control and reduced production costs. In fact, a study indicates that automated sealing processes can increase packaging line speeds by up to 30%. By leveraging these advancements, businesses can not only improve their production capabilities but also meet the growing demand for sustainable practices.

Tips: Consider transitioning to materials that are certified compostable or recyclable to align with consumer preferences. Additionally, investing in automation can significantly streamline your operations and improve efficiency. Regularly updating your equipment to incorporate the latest technologies will not only keep your business competitive but also contribute to a more sustainable future in tray sealing.

Related Posts

-

2025 Guide: How to Choose the Best Stock Clamshell Packaging for Your Products

-

Top 10 Shipping Trays You Need for Secure and Efficient Deliveries

-

Exploring the Future of Plastic Blister Packaging: Innovations and Sustainability Trends Behind 2023's Market Growth

-

Top 10 Clamshell Packaging Machines: Best Options for Your Business Needs

-

Why Choose Stock Blister Packaging for Your Product Needs

-

Exploring Market Trends for Stock Clamshells at the 138th Canton Fair in 2025