2026 Top Blister Packaging Machine Innovations and Trends?

In the rapidly evolving world of packaging, the blister packaging machine stands out as a key innovation. Experts in the field have noted significant advancements shaping its future. Dr. Emily Tran, a leading authority in packaging technology, states, "Every advancement in blister packaging reflects the industry's commitment to efficiency and sustainability."

The trends for 2026 highlight the integration of smart technology. Machines are becoming more automated and user-friendly. This shift allows for quicker production times and reduced waste. Brands are prioritizing eco-friendly materials, driven by consumer demand for sustainability.

However, challenges remain. Not every company can invest in the latest technology. Some still rely on outdated methods. This disparity can hinder efficiency and growth in the industry. As the market evolves, adapting to innovations in blister packaging machines will be crucial for success.

Key Innovations in Blister Packaging Machines for 2026

The blister packaging industry is evolving rapidly. In 2026, several key innovations are set to reshape this sector. Automation and smart technology are leading the way. Machines equipped with AI can optimize production processes, ensuring minimal waste. This can significantly reduce costs and improve efficiency.

Sustainability is another critical focus. Eco-friendly materials are becoming more prevalent, replacing traditional plastics. Manufacturers are exploring biodegradable options for blister packs. These innovations aim to reduce environmental impact. However, the shift to sustainable practices can be challenging. High production costs and limited material availability pose significant hurdles.

Customization in blister packaging is also gaining traction. Businesses want unique designs that cater to specific consumer needs. Machines that allow easy adjustments can help manufacturers respond quickly to market demands. Yet, finding the balance between customization and production speed remains a challenge for many. The need for continuous improvement in these areas is evident. The landscape of blister packaging is indeed complex, and it requires ongoing reflection and adjustment.

Emerging Materials Enhancing Blister Packaging Efficiency

Emerging materials are reshaping blister packaging in 2026. These innovations focus on improving efficiency and sustainability. Bio-based plastics are gaining traction. They reduce environmental impact while maintaining durability. These materials are lightweight and can easily mold into various shapes.

Another exciting development is the use of smart packaging. This concept integrates sensors into blister packs. These sensors monitor freshness and ensure product safety. They provide real-time information to consumers. However, not all smart technologies are flawless. Some have reliability issues. Continuous testing is crucial to improve these systems.

Recyclable materials are also at the forefront. They enhance waste management efforts but can present challenges. Ensuring compatibility with existing recycling systems can be complex. The industry must work together to create effective solutions. This collaboration is essential for maximizing the benefits of new materials. Each innovation might have its hurdles, but progress is inevitable.

2026 Top Blister Packaging Machine Innovations and Trends

| Innovation | Key Features | Emerging Materials | Efficiency Gains |

|---|---|---|---|

| Smart Sensors Integration | Real-time monitoring and adjustments | Biodegradable plastics | 20% reduction in waste |

| AI-Driven Design | Optimized packaging based on data | Recyclable barrier films | 15% increase in product life |

| Modular Machine Design | Flexible production layouts | Natural cellulose materials | 10% increase in throughput |

| Enhanced Sealing Technology | Improved hermetic sealing | Multilayer laminated films | 30% reduction in product spoilage |

Automation Trends Transforming the Blister Packaging Industry

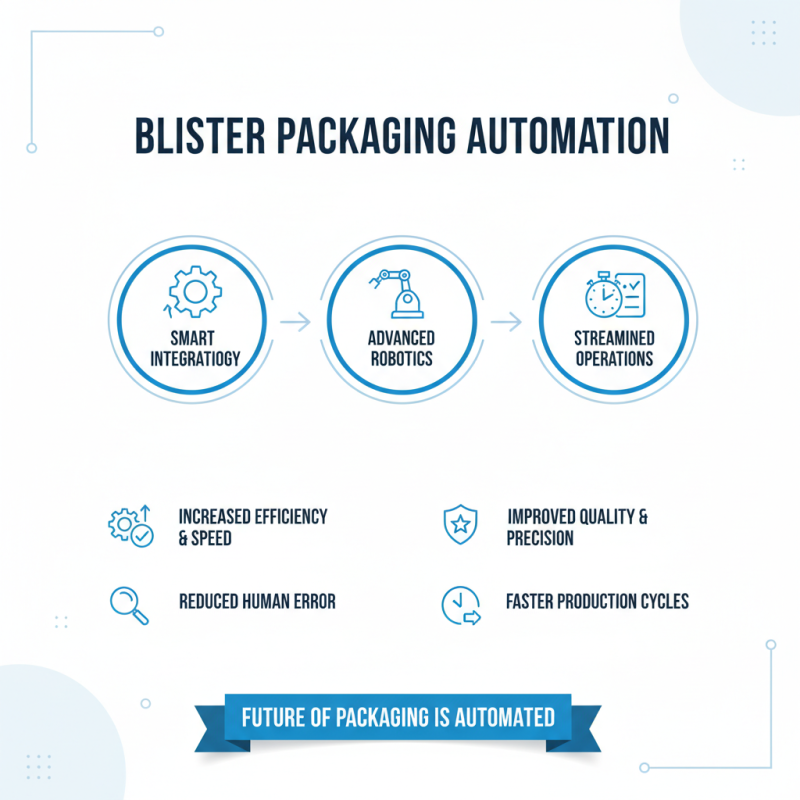

The blister packaging industry is undergoing significant changes due to automation trends. With the rise of smart technology, manufacturers can streamline operations. Automated systems reduce human error and increase efficiency. This shift allows for faster production cycles. By integrating advanced robotics, the quality of packaging improves as well. Tasks once done by hand are now completed with precision.

While automation offers many advantages, challenges remain. Initial investment costs can be high. Not all companies can afford the latest machinery. Moreover, the workforce must adapt to new technologies. Training is essential to keep employees relevant in an automated world. This transition may lead to job displacement, causing concern for many workers. The balance between efficiency and employment is a complex issue.

Utilizing data analytics is becoming commonplace. It helps optimize production processes and minimize waste. However, relying too heavily on data can lead to oversight. Manufacturers should remember the value of human intuition. A combination of technology and human insight may yield the best results. Industry players must continually reflect on these dynamics to foster sustainable growth.

Sustainability Practices in Blister Packaging Machine Design

Blister packaging has evolved significantly. As sustainability takes center stage, innovations in machine design are crucial. Companies focus on reducing waste, energy consumption, and using eco-friendly materials.

Many designers are opting for recyclable materials. Using bioplastics can minimize environmental impact. This shift not only adheres to regulations but also meets consumer demands. Yet, challenges remain. Not all materials perform equally in production.

Tips: Consider sourcing local materials to reduce carbon footprints. Always review materials for recycling opportunities. Involve the team in brainstorming sessions for innovative ideas.

It's also vital to address energy use. Sustainable machines consume less power. However, adapting older machines may require investment. Some manufacturers resist these upgrades. This hesitation can hinder progress. Evaluate the long-term gains versus initial costs. Embracing sustainability isn't just a trend; it's a necessity.

2026 Blister Packaging Machine Innovations Trends

Future Technologies Impacting Blister Packaging Performance

Blister packaging is evolving rapidly. The integration of smart technologies is transforming how these packages function. For instance, sensors can now monitor temperature and humidity levels, ensuring product integrity. This innovation is crucial for pharmaceuticals and food products, where freshness is essential. However, the cost of these technologies can be prohibitive for smaller manufacturers.

Automation is another significant trend. Advanced machines can produce blister packs at high speeds and with precision. This efficiency helps meet increasing demand. Yet, the reliance on automation sometimes leads to a loss of craftsmanship. Some manufacturers struggle to balance automation with traditional methods, resulting in inconsistencies in quality.

Sustainability is also emerging as a guiding principle. Biodegradable materials are being explored, offering eco-friendly alternatives. This shift is vital, but challenges remain. Developing new materials that meet safety standards while being cost-effective is complex. As the industry shifts towards these innovations, the future looks promising yet uncertain. Each advancement brings opportunities and challenges that need careful consideration.

Related Posts

-

Understanding the Growth and Efficiency of Blister Card Packaging Machines in the Modern Packaging Industry

-

Understanding the Role of Blister Packaging Machines in Modern Manufacturing Processes

-

5 Essential Tips for Choosing the Best Blister Packaging Materials

-

2025 Top 5 Stock Blister Packaging Solutions for Modern Businesses

-

Why Choose Stock Blister Packaging for Your Product Needs

-

Why Stock Blister Packaging is Essential for Modern Retail Solutions