2026 Top Tray Sealing Machine Features and Benefits Explained?

In the fast-paced packaging world, the tray sealing machine stands out. This innovative device is essential for enhancing food safety and extending shelf life. With 2026 on the horizon, new features and benefits are being introduced.

Modern tray sealing machines offer precision and efficiency. They ensure consistent sealing, which reduces the risk of contamination. Users appreciate how these machines can handle various materials. This flexibility makes them suitable for different industries, from food to electronics.

However, not every tray sealing machine is perfect. Some may struggle with outdated technology or maintenance challenges. Users often reflect on their experiences, seeking improvements. Understanding the nuances of these machines is crucial for maximizing their potential.

Overview of Tray Sealing Machines in 2026

In 2026, tray sealing machines have evolved significantly. These machines are essential in food packaging. They ensure products remain fresh and safe. The technology focuses on efficiency and ease of use. Users can expect quicker sealing times and better product integrity.

The latest features include adjustable sealing temperatures and faster cycles. These improvements enhance packaging consistency. However, some machines may still require frequent maintenance. This can disrupt production if not addressed. Keeping an eye on performance is crucial.

Tips: Ensure staff is trained on machine operation. Regularly check seals for quality. Small adjustments can lead to better outcomes. Overall, while advancements have been impressive, some challenges remain. Always prioritize testing before full-scale production.

Key Features of Modern Tray Sealing Machines

Modern tray sealing machines are vital in various industries. They ensure food products remain fresh. One key feature is the adjustable sealing temperature. This allows for different materials to be sealed effectively. Food safety is paramount, and precise control prevents contamination.

Another essential feature is the machine's speed. Faster sealing reduces production time. However, it can sometimes lead to mistakes. Operators need to monitor the process closely. The ease of operation is also crucial. User-friendly interfaces make training quicker. Yet, some workers still face challenges adapting to new technology.

Innovative designs play a significant role too. Many machines are now compact, saving valuable floor space. However, efficiency could be improved. Regular maintenance is often overlooked. A well-maintained machine can work wonders, but neglect may lead to downtime. Overall, while modern machines are impressive, their effectiveness hinges on careful use and ongoing attention.

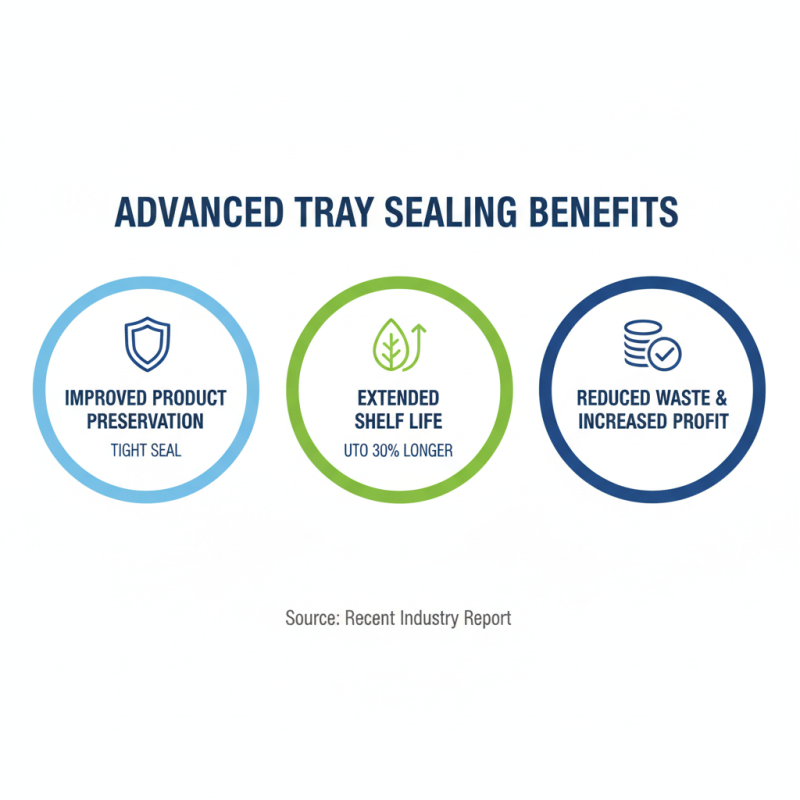

Benefits of Using Advanced Tray Sealing Technology

Advanced tray sealing technology offers multiple benefits for manufacturers. It improves product preservation by providing a tight seal, significantly reducing spoilage. According to a recent industry report, sealed trays can extend shelf life by up to 30%. This is crucial for businesses aiming to minimize waste and maximize profitability.

Cost efficiency is another hallmark of advanced tray sealing systems. The machines reduce material usage by optimizing film application. This can lead to substantial savings on packaging costs, reinforcing a company’s bottom line. A study indicated that companies could save around 20-25% on packaging expenses with the right sealing technology.

However, some challenges remain. Adapting to new technologies can require a learning curve for staff. It may also necessitate initial investment in updated equipment. These considerations reflect the ongoing need for training and development in the industry. As technology evolves, staying updated becomes essential for competitive advantage.

Applications of Tray Sealing Machines Across Industries

Tray sealing machines are increasingly used in various industries. In food production, they package meals, ensuring freshness. These machines create a tight seal that extends shelf life. They not only reduce spoilage but also enhance the presentation of products. This is particularly important in ready-to-eat meals. Visual appeal can influence consumer choices.

In the medical field, tray sealing machines play a vital role. They package sterile instruments and supplies. Maintaining sterility is crucial for patient safety. A minor error in sealing can lead to contamination. It's a constant challenge in maintaining efficiency and accuracy. Additionally, pharmaceuticals utilize these machines for packaging drugs. This application requires precise sealing to protect contents.

While tray sealing machines offer many benefits, there are limitations to consider. Not all materials are compatible. Improper sealing can lead to product loss. Regular maintenance is necessary to ensure optimal performance. Professionals must stay vigilant to avoid common pitfalls. This reflects the importance of training and experience in operating these machines.

Future Trends in Tray Sealing Technology and Innovations

The future of tray sealing technology looks promising, with several innovative trends emerging. Automation is becoming a key focus. Machines now come equipped with advanced sensors and AI integration. These features enhance accuracy and maintain consistency. Automated solutions reduce human error, yet they require careful implementation.

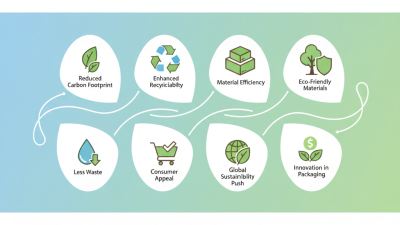

Sustainability is another critical trend in tray sealing. Manufacturers are exploring eco-friendly materials and recyclable packaging. This shift aims to meet consumer demand for greener practices. However, it is challenging. Balancing cost and sustainability can be tricky. Companies must assess the trade-offs while pushing for innovation.

The evolution of smart technology plays a crucial role as well. Real-time monitoring allows for quick adjustments during production. This leads to higher efficiency and reduced waste. Yet, there’s an unavoidable learning curve. Industries must train personnel to adapt to these new systems. Embracing the latest technologies may create initial hurdles, but the long-term benefits could be significant.

2026 Top Tray Sealing Machine Features and Benefits Explained

| Feature | Description | Benefits | Future Trends |

|---|---|---|---|

| High-Speed Operation | Capable of sealing up to 20 trays per minute. | Increased efficiency and productivity in packaging lines. | Automation and robotics integration. |

| User-Friendly Interface | Touchscreen controls with easy navigation. | Reduced training time for operators. | Smart technology enhancements. |

| Versatile Sealing Options | Supports various tray materials including plastic and aluminum. | Flexibility for different product types. | Sustainability in packaging solutions. |

| Smart Monitoring | Real-time monitoring of sealing quality. | Improved product quality and reduced waste. | Data analytics for predictive maintenance. |

| Compact Design | Space-saving, suitable for various production floors. | Maximizes workspace efficiency. | Modularity for easy upgrades. |

Related Posts

-

Exploring the Benefits of Blister Card Packaging for Eco-Friendly Product Marketing

-

What is a Blister Card and How Does It Work?

-

Top 10 Benefits of Clam Packaging for Sustainable Product Delivery

-

Understanding the Role of Blister Packaging Machines in Modern Manufacturing Processes

-

Understanding the Benefits of Clamshell Packaging Machines for Eco-Friendly Product Solutions

-

Best Thermoform Packaging Options for Your Business Needs?