10 Best Bulk Clamshell Packaging Solutions You Need to Consider for Your Business

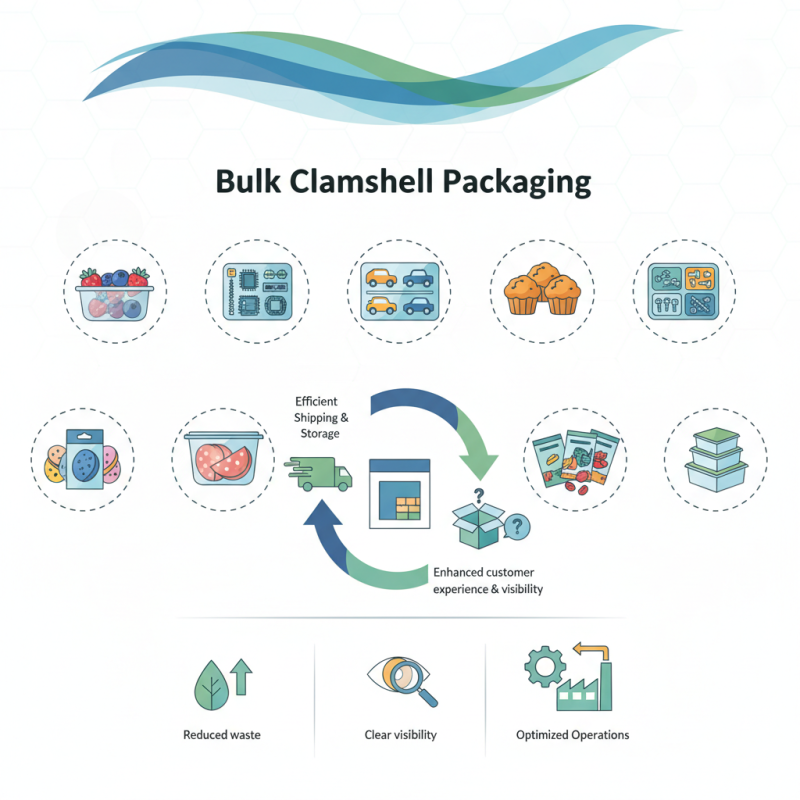

In the ever-evolving landscape of packaging solutions, businesses must continuously seek innovative and efficient ways to meet consumer demands. One such solution gaining traction is bulk clamshell packaging. Renowned packaging industry expert Michael Reynolds stated, “Bulk clamshell packaging not only offers superior protection for products but also enhances the customer experience through its convenience and visibility.” This type of packaging allows companies to streamline their shipping and storage processes while ensuring that their products remain safe and intact.

As companies explore their options, it's crucial to consider the various benefits that bulk clamshell packaging can offer. From reducing packaging waste to providing clear visibility of goods, this solution meets the practical needs of both businesses and consumers alike. However, selecting the appropriate packaging can be daunting, given the myriad of available options. Therefore, understanding the best bulk clamshell packaging solutions becomes essential for businesses aiming to optimize their operations and adapt to market trends effectively.

Overview of Clamshell Packaging and Its Benefits

Clamshell packaging has become a popular choice for businesses seeking effective and versatile solutions for product containment. Characterized by its hinged design, this type of packaging typically consists of two halves that can be easily sealed and opened, providing an attractive and functional way to showcase products. Its transparent nature allows consumers to view items without removing them from the package, enhancing visual appeal and accessibility for retailers and customers alike.

The benefits of clamshell packaging are numerous. Firstly, it offers excellent protection against damage and contamination, making it suitable for a variety of products, from electronics to food items. This durability ensures that products remain intact during transportation and handling, thus reducing returns and increasing customer satisfaction. Additionally, clamshells can be designed with features such as tamper-evidence or child-resistant closures, providing added security for sensitive items. Moreover, the environmental impact of clamshell packaging can be minimized by opting for recyclable materials, appealing to eco-conscious consumers and supporting sustainability initiatives within businesses.

Key Factors to Consider When Choosing Bulk Clamshell Packaging

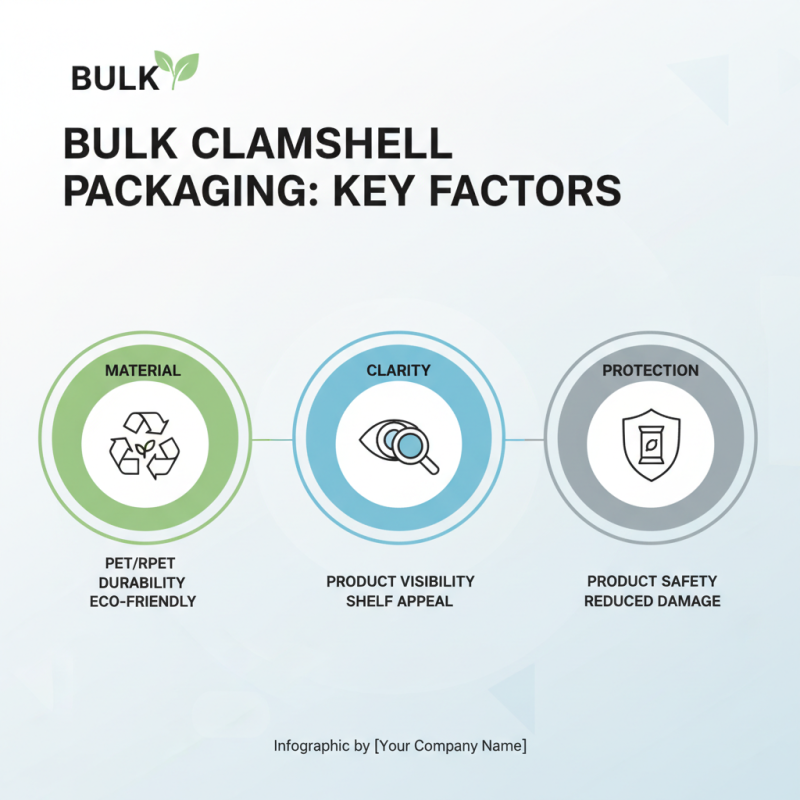

When selecting bulk clamshell packaging for your business, several key factors should be top of mind to ensure you make the right choice. First and foremost, consider the material used in the clamshell design. Durable materials, such as PET or RPET, offer better protection for your products while also appealing to environmentally conscious consumers. Additionally, the choice of material influences the packaging's clarity, which can enhance product visibility and appeal on the retail shelf.

Another important factor is the size and customization of the clamshell packaging. It's crucial to select a size that fits your products snugly to prevent movement and potential damage during transit. Moreover, customization options, such as printing or branding, can create a professional look and help differentiate your product in a competitive market. Lastly, think about the ease of use for both packaging and unpackaging; features like perforated openings or tamper-evident seals can improve customer satisfaction and streamline processes in your supply chain. By evaluating these aspects carefully, you can select bulk clamshell packaging that not only protects your products but also enhances your brand's market presence.

Top 10 Bulk Clamshell Packaging Solutions for Various Industries

When it comes to selecting the best bulk clamshell packaging solutions, businesses across various industries must consider specific needs such as product protection, visibility, and sustainability. The appeal of clamshell packaging lies in its ability to securely hold items while providing ample display opportunities. For instance, the food sector benefits immensely from this packaging type, as it keeps products like fresh produce or ready-to-eat meals protected from contamination, extending their shelf life and maintaining freshness.

Additionally, the retail and manufacturing industries utilize bulk clamshell packaging to ensure safe transportation and secure storage of delicate items like electronics or cosmetics. These solutions not only minimize the risk of damage but also allow for efficient inventory management. Sustainability is increasingly becoming a priority, leading many companies to seek out biodegradable or recyclable clamshell options, which cater to environmentally conscious consumers. By weighing the various functional and ecological aspects of clamshell packaging, businesses can select the best solutions that align with their operational requirements and customer preferences.

10 Best Bulk Clamshell Packaging Solutions for Various Industries

Sustainability in Clamshell Packaging: Eco-Friendly Options

Sustainability in clamshell packaging has gained significant attention as businesses seek to minimize their environmental impact. Traditional plastic clamshells, often made from petroleum-based materials, contribute to a growing problem of plastic waste. However, eco-friendly options are emerging, allowing companies to package their products responsibly. For example, bioplastics derived from renewable resources such as corn starch or sugarcane offer a compostable alternative that can reduce landfill contributions when properly processed.

In addition to bioplastics, manufacturers are increasingly exploring recycled materials for clamshell packaging. Utilizing post-consumer recycled plastics can significantly lower the carbon footprint associated with production. These sustainable options not only help businesses meet regulatory requirements and consumer demand for eco-conscious products but also enhance their brand reputation. By adopting these green packaging solutions, companies can proactively participate in the global movement towards sustainability while also fulfilling their business needs.

Tips for Implementing Clamshell Packaging in Your Business Operations

When implementing clamshell packaging in your business operations, it's essential to consider several key strategies that can enhance both your product presentation and operational efficiency. According to a report by Smithers Pira, the global market for rigid plastic packaging, which includes clamshells, is projected to reach approximately $300 billion by 2024, reflecting the growing demand for sustainable and attractive packaging solutions. To start, ensure that your clamshell designs are tailored to fit your product securely while offering visibility, which can significantly improve consumer appeal and encourage impulse purchases.

Another crucial tip is to streamline your packaging process. Efficient machinery and automated systems can dramatically reduce labor costs and increase production rates. A study from the Packaging Machinery Manufacturers Institute indicates that businesses investing in automated packaging systems can experience an average productivity increase of 25-30%. Training staff on these systems ensures smoother operations and minimizes errors, ultimately enhancing your supply chain reliability. Additionally, sourcing clamshells from providers that emphasize sustainability—whether through recyclable materials or reduced environmental impact—can also align with consumer preferences, as 73% of consumers indicate they prefer brands that utilize eco-friendly packaging options.

10 Best Bulk Clamshell Packaging Solutions You Need to Consider for Your Business

| Clamshell Type | Material | Size (inches) | Weight Capacity (lbs) | Seal Type | Customization Options |

|---|---|---|---|---|---|

| Standard Clamshell | PET | 6 x 8 | 2 | Hinge | Printing |

| Deep Clamshell | PVC | 8 x 10 | 3 | Snap | Labeling |

| Custom-Made Clamshell | Biodegradable | 5 x 7 | 2.5 | Hinge | Shape & Size |

| Retail Clamshell | Recyclable PET | 6 x 6 | 1.5 | Push-to-open | Printing & Colors |

| Ventilated Clamshell | Polypropylene | 7 x 9 | 4 | Hinge | Size Customization |

Related Posts

-

2025 Guide: How to Choose the Best Stock Clamshell Packaging for Your Products

-

Essential Checklist for Choosing the Right Plastic Clamshells for Your Products

-

How to Choose the Right Clear Clamshell Packaging for Your Products

-

Exploring Market Trends for Stock Clamshells at the 138th Canton Fair in 2025

-

Maximize Freshness and Convenience with Innovative Bulk Clamshell Packaging Solutions

-

The Rising Demand for Plastic Clamshell Packaging in Sustainable Retail Solutions