Best Thermoform Packaging Options for Your Business Needs?

Thermoform packaging has become a vital component in various industries, from food to medical. As of 2023, the global thermoforming market is projected to reach approximately $12 billion, with a CAGR of 5.4% from 2023 to 2029. This growth underscores the increasing demand for efficient and sustainable packaging solutions. Companies are realizing that thermoform packaging offers customization, durability, and cost-effectiveness.

However, not all thermoform packaging solutions are equal. Businesses face challenges in selecting the right option that meets their specific needs. Some may struggle with material choices, while others might overlook the environmental impact. Understanding the variety of thermoforming materials available can lead to better decision-making. By prioritizing innovation and sustainability, companies can enhance their product's market appeal and reduce waste.

In this ever-evolving landscape, making informed choices in thermoform packaging can significantly influence a company’s success. With the right approach, businesses can balance functionality and eco-friendliness, aligning with consumer preferences for responsible packaging.

Understanding Thermoform Packaging: Key Concepts and Benefits

Thermoform packaging is becoming increasingly important in various industries. This process involves heating plastic sheets and molding them into shape. According to a recent report by Smithers Pira, the global thermoforming market is expected to reach $12 billion by 2024. This growth is driven by its versatility and efficiency in packaging solutions.

One of the key benefits of thermoform packaging is its customization options. Businesses can create specific shapes and sizes to fit their products. For example, packaging for food items often requires a perfect fit to maintain freshness. However, customization can also pose challenges. Companies must balance design with cost-effectiveness.

Sustainability is another significant aspect. Several studies indicate that thermoform packaging can reduce material waste by up to 30%. While appealing, companies should reflect on how to recycle or reuse their packaging. As consumer awareness around sustainability grows, brands face pressure to adopt eco-friendly practices. This transition, although beneficial, may require time and investment to implement effectively.

Best Thermoform Packaging Options for Your Business Needs

| Packaging Type | Material | Thickness (mm) | Key Benefits | Typical Applications |

|---|---|---|---|---|

| Blister Packaging | PVC | 0.5-1.5 | Visibility, product protection, cost-effective | Pharmaceuticals, electronics |

| Clamshell Packaging | PET | 1-2 | Reusable, durable, tamper-evident | Retail, consumer goods |

| Tray Packaging | PS | 1-3 | Stackable, customizable, efficient | Food, electronics |

| Custom Thermal Molding | ABS | 2-5 | High strength, custom designs | Automotive, industrial parts |

| Skin Packaging | OPP | 0.3-1.0 | Freshness retention, attractive presentation | Meat, cheese, electronics |

Types of Thermoform Packaging Solutions for Various Industries

Thermoform packaging is gaining traction across various industries due to its versatility. The food sector, for instance, values these solutions for their ability to enhance shelf life. A report from the Freedonia Group highlights that the market for thermoformed packaging in food is expected to surpass $12 billion by 2025. This growth illustrates the increasing demand for convenience and sustainability among consumers.

In the medical field, thermoform packaging is used for sterile equipment and devices. It provides a protective barrier, ensuring product safety. However, there are challenges. Some materials can compromise recycling efforts. According to a study by Smithers Pira, the medical packaging market is projected to grow at a CAGR of 6.2% through 2024. This growth pushes companies to rethink their material choices for better environmental compliance.

Packaging for consumer goods also benefits from thermoforming. It allows for customized shapes and designs, making products more attractive. An industry report found that 70% of consumers base their purchase decisions on packaging design. Not all thermoform solutions are perfect, as some may not meet durability expectations. Companies must test various materials to find optimal solutions for specific product needs.

Best Thermoform Packaging Options for Your Business Needs

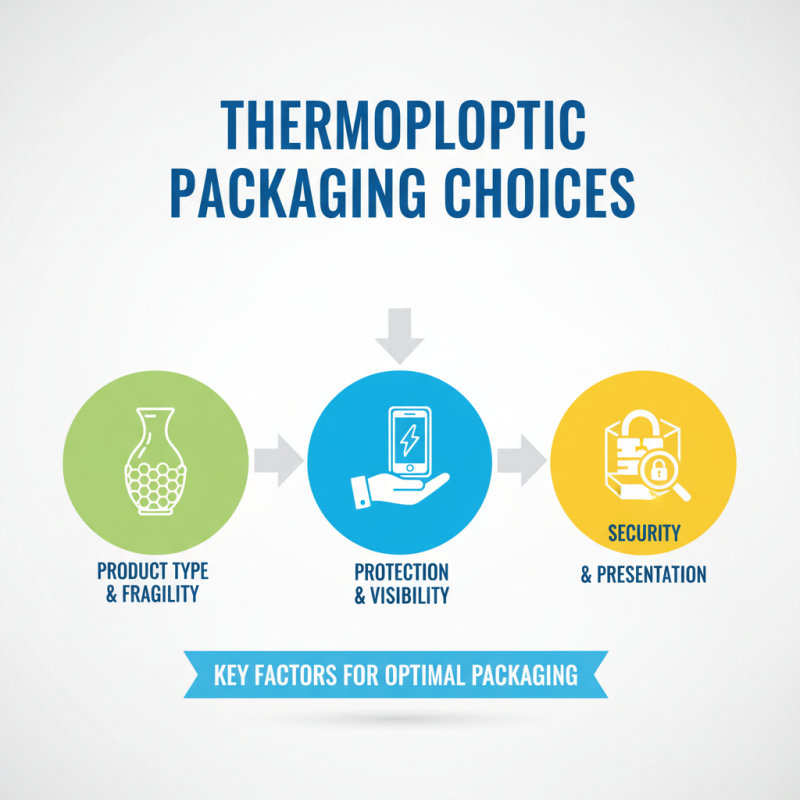

Factors to Consider When Choosing Thermoform Packaging Options

When choosing thermoplastic packaging options, several factors come into play. The product type is crucial. Different products require different levels of protection and design. For example, fragile items may need thicker material. Focus on how the packaging can enhance product visibility while also providing security.

Material selection is another important consideration. The type of plastic used can affect both cost and sustainability. Some materials are more eco-friendly but may not offer the same level of durability. Think about the environmental impact of your packaging choices. Balancing functionality and ecological responsibility is not an easy task.

Design options also deserve attention. Attractive packaging can draw consumers in. However, it must also be practical. Striking the right balance between aesthetics and usability can be challenging. It's essential to test various designs. Each trial can provide insights for improvements. Be open to feedback. Adjustments based on real-world usage often lead to better outcomes.

Sustainability in Thermoform Packaging: Eco-Friendly Alternatives

Sustainability is crucial in today’s packaging industry. Many businesses seek eco-friendly thermoform options. These alternatives help reduce environmental impact. Biodegradable materials are a great choice. They decompose naturally and minimize waste.

Using recycled materials can also be effective. Many thermoform products now incorporate post-consumer plastics. This reduces the need for new materials and lessens pollution. It's essential to work with suppliers dedicated to eco-friendly practices. Your choice in packaging can communicate your values to consumers.

Tips for selecting sustainable options: Look for certifications that guarantee eco-friendliness. Inquire about the production process. Assess whether the materials can be recycled or reused. Making informed choices can enhance your brand’s commitment to sustainability and appeal to eco-conscious customers.

Cost-Effectiveness of Thermoform Packaging for Business Savings

Thermoform packaging offers businesses a cost-effective solution. Utilizing sheets of plastic, manufacturers create custom shapes efficiently. This reduces both production time and waste. For many businesses, switching to thermoform means significant savings. The lightweight nature of the material lowers shipping costs too.

Investing in thermoform packaging can feel daunting. Initial costs may seem high, but long-term benefits can outweigh them. Customization leads to better product presentation and potential increased sales. However, not every company sees immediate improvements. Research and testing are vital before transitioning.

The flexibility of thermoform allows for a wide range of applications. This versatility can cater to various industries. Despite its advantages, some businesses face challenges in adapting. Understanding material properties is essential for optimal results. Take the time to analyze your needs before committing to a switch. A thoughtful approach can lead to better decision-making in the long run.

Related Posts

-

7 Tips for Maximizing Efficiency with Thermoform Packaging

-

Exploring Innovations in Automatic Tray Sealing Machines at the 138th Canton Fair 2025

-

What is a Blister Pack and How Does it Work in Packaging Solutions

-

What is an Automatic Blister Packing Machine and How Does It Work

-

What is the Importance of Blister Packaging Machine in Modern Manufacturing

-

Top 10 Shipping Trays You Need for Secure and Efficient Deliveries