What is a Blister Card and How Does It Work?

Blister cards are widely used in packaging, particularly in the pharmaceutical and consumer goods industries. According to a recent market report, the blister packaging market is projected to grow by 5.1% annually, reaching USD 27.6 billion by 2027. This growth reflects the increasing demand for efficient packaging solutions that enhance product visibility and safety.

A blister card typically consists of a plastic blister adhered to a card with individual compartments for products. This design not only protects items but also allows consumers to easily view them. However, the production process can lead to waste and environmental concerns, sparking discussions about sustainability. Many companies are now seeking eco-friendly alternatives to traditional materials.

Despite its benefits, the blister card system is not flawless. Issues like difficulty in opening and child safety remain significant. Consumers often struggle with removing items without damaging the packaging. This highlights the need for improvement in design and functionality. Addressing these challenges can enhance user experience and ensure safer options in the market.

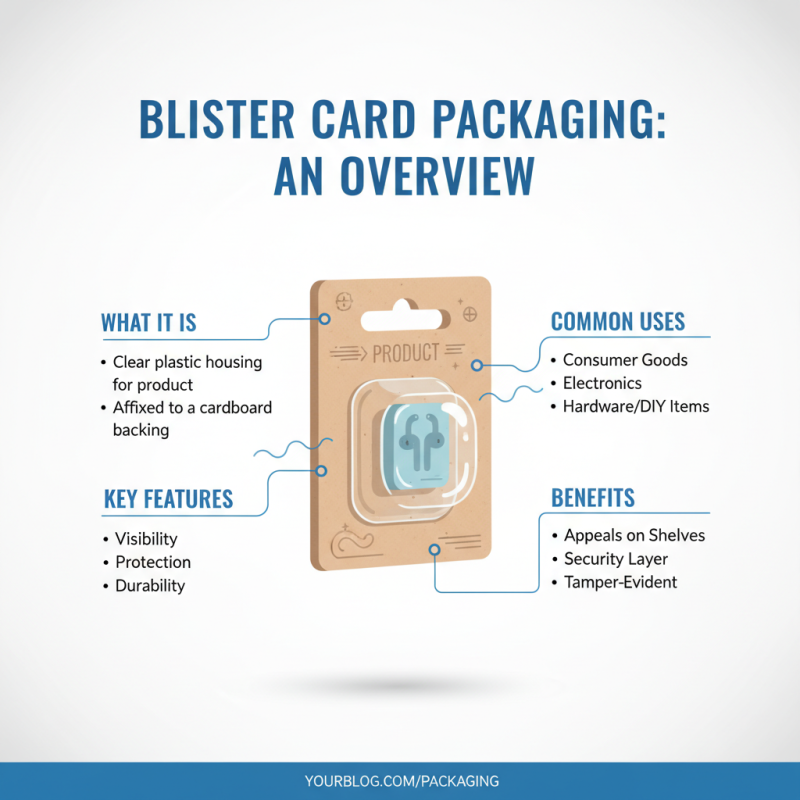

What is a Blister Card? An Overview of Its Definition

A blister card is a packaging solution commonly used for consumer goods. It usually consists of a clear plastic section that houses the product. This section is then affixed to a cardboard backing. The design allows for visibility and protection, making products appealing on store shelves. Blister cards are also durable, adding a layer of safety to the item inside.

When it comes to utilizing blister cards effectively, consider the following tips. Make sure the plastic is of good quality. Poor plastic can lead to damage during shipping. Also, think about the design. A clean, simple layout can attract customers. Cluttered designs might confuse them. Ensure that the text is easy to read.

Many businesses overlook the importance of proper sealing. A poorly sealed blister card can lead to product tampering. It's a mistake that can cost you customer trust. Test your designs with real users. Pay attention to their feedback. This way, you can improve your packaging before mass production begins. A well thought out blister card can enhance your product's marketability.

The Components of a Blister Card: Materials and Design Features

A blister card is a unique packaging solution that combines functionality with visual appeal. Typically made from plastic, the key components include a backing card and a plastic blister. The blister is where the product is housed, providing a clear view. It allows consumers to see what they are buying.

The design features of a blister card are crucial. The backing card often provides important information. It can include instructions, branding, and other necessary details. Sometimes, the card is made from recycled materials, showcasing a commitment to sustainability. It’s tough to balance aesthetics and durability. If the card is too flimsy, it may not protect the product well. Conversely, if it’s too thick, it can be cumbersome.

In terms of materials, the plastic used for the blister needs to be sturdy. But, it should not be excessively hard. Finding the right balance is challenging. For instance, using materials that are environmentally friendly could compromise structure. Some designs neglect to prioritize user experience. Sharp edges may deter users, while complex openings can frustrate them. It's essential to refine these aspects continually.

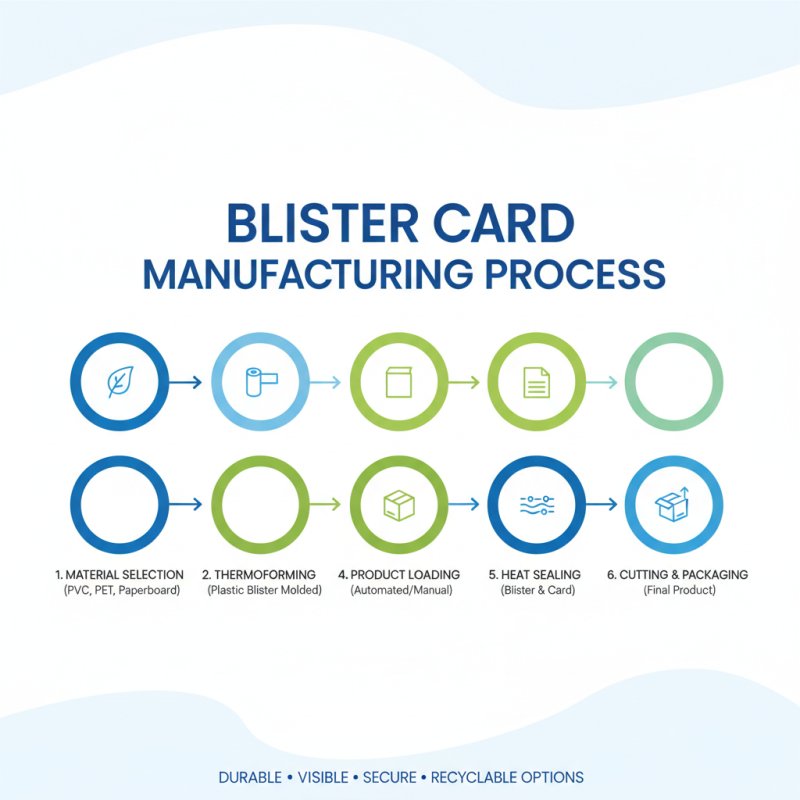

How Blister Cards Are Manufactured: A Step-by-Step Process

Blister cards are a popular packaging solution in various industries. Their manufacturing process is intricate and requires several steps. Typically, the process starts with the selection of materials. Blister cards are often made from PVC, PET, or paperboard, each having distinct properties. For example, PVC is durable, while paperboard offers a more eco-friendly option.

Next, the card is printed with necessary information. This includes instructions, graphics, and branding elements. According to industry reports, up to 70% of packaging decisions are influenced by visual appeal. After printing, the forming process begins. A heat-based method creates the blisters that hold the products securely. Data suggests that improper formation could result in a 30% increase in return rates due to product damage.

Finally, the filling and sealing process occurs. Cards are filled manually or automatically. Then, they are sealed using heat or adhesive. This is a critical step, as proper sealing prevents tampering and ensures product integrity. Yet, there are challenges. Inconsistent sealing can lead to product spoilage or consumer dissatisfaction. Companies must continuously refine their processes to minimize errors. The complexity of blister card production highlights the importance of attention to detail in achieving effective packaging solutions.

Advantages of Using Blister Cards for Packaging and Protection

Blister cards are gaining popularity in the packaging industry. Their protective features and visual appeal make them an excellent choice for various products. According to a report by Smithers Pira, the global blister packaging market is projected to reach $7.5 billion by 2025. This is indicative of their increasing importance.

One of the key advantages of blister cards is product visibility. Consumers can see the product clearly, enhancing its attractiveness. A study found that products displayed in blister packaging had a 25% higher purchase rate compared to traditional packaging. This is vital in competitive markets where shelf appeal can make or break sales.

Another benefit is the protective nature of blister cards. They provide a barrier against moisture, dust, and damage. This is essential for maintaining the quality of products, especially in pharmaceuticals. However, it’s worth noting that blister packaging may not be as environmentally friendly as alternative solutions. The challenge remains in balancing product protection with sustainability. Finding ways to innovate in materials could be crucial for the industry's future.

What is a Blister Card and How Does It Work? - Advantages of Using Blister Cards for Packaging and Protection

| Feature | Description | Advantages |

|---|---|---|

| Material | Typically made from PVC, PET, or PP | Durable and resistant to moisture and impact |

| Design Flexibility | Customizable shapes and sizes | Allows for branding and product visibility |

| Protection | Holds products securely with a sealed backing | Prevents damage and tampering |

| Cost-Effectiveness | Low manufacturing costs due to mass production | Reduces overall packaging expenses |

| User-Friendly | Easy to open while maintaining security | Enhances user experience |

Common Applications of Blister Cards in Various Industries

Blister cards find common applications across various industries. The pharmaceutical sector extensively uses them for packaging medications. A report from Smithers Pira states that blister packaging accounts for nearly 30% of the global pharmaceutical packaging market, due to its effectiveness in protecting drugs from moisture and contamination. This packaging format allows for easy identification of dosage while reducing the risk of misuse.

In the healthcare industry, blister cards are also vital for medical devices. They provide a sterile environment, which is crucial for items like syringes or surgical instruments. According to the Healthcare Packaging Association, the demand for such packaging is increasing by approximately 5% annually. Yet, challenges remain. Not all materials provide adequate protection against external factors, leading to potential product failures.

Another important application lies in the consumer goods sector. Blister cards frequently package electronics, toys, and cosmetics. They enhance product visibility on retail shelves. However, they can also result in excessive waste. The challenge is finding a balance between presentation and sustainability. Reports show that around 70% of consumers prefer eco-friendly packaging options. This highlights a growing need for innovation in blister card materials.

Related Posts

-

Why Stock Blister Packaging is Essential for Modern Retail Solutions

-

What is a Blister Pack and How Does it Work in Packaging Solutions

-

How to Optimize Your Blister Card Packaging for Enhanced Product Visibility and Sales Performance

-

How to Choose the Right Blister Packs for Your Products

-

Exploring the Future of Plastic Blister Packaging: Innovations and Sustainability Trends Behind 2023's Market Growth

-

2025 Top 5 Stock Blister Packaging Solutions for Modern Businesses