How to Choose the Best Plastic Clamshell Containers for Your Packaging Needs

In the competitive world of packaging, selecting the most suitable containers is crucial for both brand identity and product preservation. Among the various options available, plastic clamshell containers stand out for their versatility and efficiency. According to the latest report from Smithers Pira, the global demand for plastic clamshell containers is projected to reach over $2 billion by 2025, driven by their increasing use in food service, retail, and industrial applications. This growth underscores the importance of understanding how to choose the right clamshell for your specific needs.

Expert packaging consultant, Dr. Emily Tran, highlights the significance of making informed choices in her statement: "The right packaging can not only enhance product visibility on store shelves but also offer superior protection throughout the supply chain." This concept is particularly relevant for businesses looking to optimize their packaging solutions while balancing cost and sustainability. As companies increasingly prioritize eco-friendly materials, selecting the best plastic clamshell containers becomes an essential strategy to meet both consumer demands and regulatory standards in the ever-evolving packaging landscape.

Expert packaging consultant, Dr. Emily Tran, highlights the significance of making informed choices in her statement: "The right packaging can not only enhance product visibility on store shelves but also offer superior protection throughout the supply chain." This concept is particularly relevant for businesses looking to optimize their packaging solutions while balancing cost and sustainability. As companies increasingly prioritize eco-friendly materials, selecting the best plastic clamshell containers becomes an essential strategy to meet both consumer demands and regulatory standards in the ever-evolving packaging landscape.

Understanding the Different Types of Plastic Clamshell Containers Available

When selecting the best plastic clamshell containers for your packaging needs, understanding the various types available is essential. Clamshell containers are popular due to their versatility and capacity to protect products while offering visibility. They come in several designs, including hinged and non-hinged options, which cater to different product shapes and sizes. According to a recent market report by Smithers Pira, the global demand for plastic packaging is projected to reach 400 million tons by 2025, highlighting the importance of choosing the right container type to meet evolving consumer preferences.

There are also several plastics commonly used in clamshell containers, such as PET, PVC, and PLA. PET is known for its excellent clarity and is recyclable, making it a sustainable choice. In contrast, PLA is a bio-based alternative that appeals to eco-conscious businesses. When selecting your clamshell, consider the type of product it will hold. For heavy or fragile items, sturdier materials and reinforced designs are advisable.

**Tips:** Always evaluate the sealability of clamshell containers to ensure product freshness, especially for perishable goods. Also, consider the aesthetic influence of clear packaging; studies indicate that consumers are more inclined to purchase products that offer visibility. Finally, it may be beneficial to test various sizes and configurations to determine the best fit for your specific packaging needs.

Key Factors to Consider When Choosing Clamshell Containers for Your Products

When selecting plastic clamshell containers for your packaging needs, there are several key factors to consider that can significantly impact the effectiveness of your product presentation and protection. First and foremost, the material of the clamshell is crucial; look for high-quality, food-grade plastics if you are packaging consumables. This ensures safety and compliance with health standards. Additionally, transparency in the material can enhance visibility, allowing customers to see the product inside, which can be a decisive factor in purchasing behavior.

Another important consideration is the size and shape of the container. It’s essential to choose a clamshell that fits your product snugly without wasting space or compromising on protection. Customizations or variances in design can also help in catching consumer attention, so evaluating options for compartments or inserts could provide added value for efficiency and presentation. Finally, take into account the sustainability aspect by exploring biodegradable or recyclable clamshells to appeal to environmentally conscious consumers, while also aligning with your brand values.

Factors to Consider When Choosing Plastic Clamshell Containers

Evaluating the Quality and Durability of Plastic Clamshell Packaging

When selecting plastic clamshell containers for packaging, evaluating their quality and durability is paramount. High-quality clamshells are often crafted from robust materials such as PET or PVC, which not only provide excellent clarity but also ensure that the containers can withstand impact. Inspecting the thickness of the plastic is essential, as thicker walls typically indicate greater strength and longevity. Additionally, consider the type of closure mechanism; a secure closure minimizes the risk of spillage and contamination, enhancing the overall functionality of the clamshell.

Durability is another critical factor that can significantly affect your packaging choice. Clamshells should be resistant to various environmental factors, including temperature fluctuations and moisture. Testing for stress resistance through drop tests can help determine how well a container will perform in transit or on retail shelves. Furthermore, consider whether the clamshell packaging is designed for reuse or recycling, as this not only impacts sustainability but also aligns with the growing consumer preference for eco-friendly packaging solutions.

Sustainability Considerations in Selecting Clamshell Packaging Options

When selecting clamshell packaging options, sustainability should be at the forefront of your decision-making process. The environmental impact of packaging materials is becoming increasingly critical as consumers demand eco-friendly solutions. Opting for biodegradable or recycled plastics can significantly reduce the carbon footprint associated with your packaging. Look for clamshell containers made from materials that can break down naturally or ones that are sourced from recycled content, thus minimizing waste in landfills.

Additionally, consider the lifecycle of the packaging. Sustainable clamshells should not only meet your current needs but also adhere to principles of reuse and recyclability. Packaging that can be repurposed by consumers or easily recycled contributes to a circular economy, reducing the need for virgin materials. By prioritizing sustainable clamshell options, businesses can not only meet regulatory requirements but also enhance their brand image, appealing to environmentally-conscious consumers and fostering loyalty in an increasingly green marketplace. Selecting the right packaging is an essential step towards a sustainable future.

How to Choose the Best Plastic Clamshell Containers for Your Packaging Needs - Sustainability Considerations in Selecting Clamshell Packaging Options

| Container Type | Material | Recyclability | Uses | Sustainability Rating |

|---|---|---|---|---|

| Standard Clamshell | PET | Yes | Food Packaging | B |

| Deep Clamshell | PLA | Yes | Produce Packaging | A |

| Hinge Lid Clamshell | PS | Limited | Bakery Items | C |

| Biodegradable Clamshell | Bagasse | Yes | Takeaway Foods | A+ |

| Multi-Compartment Clamshell | APET | Yes | Meal Kits | B+ |

Cost-Effectiveness and Bulk Purchasing of Plastic Clamshell Containers

When it comes to selecting plastic clamshell containers for your packaging requirements, cost-effectiveness and bulk purchasing are crucial factors to consider. Buying in bulk often leads to significant savings, allowing businesses to reduce their packaging costs while still maintaining quality. As clamshell containers are widely used across various industries, including food service, retail, and logistics, leveraging bulk purchasing agreements with manufacturers can result in lower per-unit prices. Additionally, many suppliers offer discounts for larger orders, which can benefit businesses looking to stock up on essential packaging solutions.

Moreover, purchasing in bulk not only saves money but also ensures consistency in your packaging materials. Having a regular supply of clamshell containers allows for better inventory management and helps streamline production processes. Businesses can avoid last-minute orders that often come at a premium price. Furthermore, consistent supplier partnerships can lead to improved product quality and reliability, making it essential to choose a reputable manufacturer that aligns with your quality standards while still offering competitive pricing.

By focusing on cost-effectiveness and bulk purchasing strategies, companies can efficiently meet their packaging needs without compromising on budget or quality.

Related Posts

-

Essential Checklist for Choosing the Right Plastic Clamshells for Your Products

-

Addressing Challenges in Clam Packaging for Optimal Product Preservation

-

How to Choose the Right Clear Clamshell Packaging for Your Products

-

Exploring Market Trends for Stock Clamshells at the 138th Canton Fair in 2025

-

Maximize Freshness and Convenience with Innovative Bulk Clamshell Packaging Solutions

-

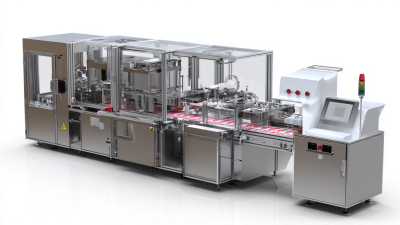

Understanding the Benefits of Clamshell Packaging Machines for Eco-Friendly Product Solutions