Why Choose a Blister Packing Machine for Your Packaging Needs?

In today’s competitive packaging industry, choosing the right method is crucial. The blister packing machine stands out for its efficiency and versatility. As John Smith, a renowned expert in packaging technology, once stated, "The blister packing machine revolutionizes how products are presented and protected."

Blister packing machines offer numerous advantages. They ensure products are safe from damage and extend shelf life. These machines can handle various materials, from pharmaceuticals to consumer goods. However, the initial investment can be a concern. Companies must weigh benefits against costs.

Many brands have seen success with this technology. Yet, others struggle to adapt. It’s essential to fully understand the machine’s capabilities. Investing in a blister packing machine might lead to better product visibility and customer satisfaction. Choosing wisely can make a significant difference in packaging needs.

Benefits of Using a Blister Packing Machine for Product Protection

Blister packing machines are increasingly favored for their ability to protect products effectively. They create airtight seals that prevent moisture and contaminants from reaching the contents. According to the Packaging Machinery Manufacturers Institute, over 25% of consumer complaints are linked to product damage during transport. This underlines the need for robust packaging solutions.

For pharmaceuticals and medical devices, blister packing offers an excellent barrier against external factors. A report from the World Health Organization states that packaging integrity is crucial for maintaining drug efficacy. Blister packs help in preserving shelf life and ensuring products remain uncontaminated until use.

However, blister packing is not without its challenges. The initial investment can be high, restricting accessibility for smaller businesses. Additionally, some users may find the tamper-evident features complex. There is also a learning curve involved in operating these machines efficiently. Thus, while blister packing machines have many benefits, companies must weigh the pros and cons before making a decision.

Types of Blister Packing Machines Available in the Market

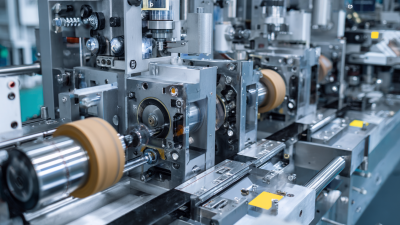

Blister packing machines come in various types, each serving different packaging needs. The most common type is the Thermoforming blister machine. This machine uses heat to shape plastic around products. It is ideal for packaging items like pills, hardware, or small electronics. The process is quick, but it may have limitations on complex shapes.

Another common type is the Cold Forming blister machine. This machine does not require heat. Instead, it uses pressure to form the packaging. It is often used for pharmaceutical products that require moisture protection. These machines can be more expensive and may demand a higher skill level to operate effectively.

There are also semi-automated and fully automated blister packing machines. Semi-automated machines are user-friendly and perfect for smaller operations. They have limitations in speed and volume. Fully automated machines handle larger batches and require less human intervention. However, they can be a more significant financial investment. Choosing the right machine is critical. It involves weighing production volume against budget and product type.

Market Share of Different Types of Blister Packing Machines

Key Features to Consider When Choosing a Blister Packing Machine

When selecting a blister packing machine, several key features require attention. The machine’s speed is crucial. If it operates too slowly, it may bottleneck production. Consider the average output needed for your products. A machine that can adapt its speed is a plus. This flexibility is essential in meeting varying demands.

The size of the blister pack is another important factor. Different products require different sizes. Ensure the machine can accommodate your specific packaging requirements. Additionally, the ease of operation matters. A complex interface can lead to mistakes. Simplicity can lead to smoother operations. Look for machines that offer user-friendly controls.

Finally, consider the machine's maintenance needs. Some models require frequent servicing, which can disrupt production. A machine with lower upkeep is often more productive. Reflecting on your needs early can help prevent headaches later. Investigate all these aspects thoroughly. Each detail contributes to the overall efficiency of your packaging process.

Applications of Blister Packing in Various Industries

Blister packing machines have diverse applications across many industries. In the pharmaceutical sector, they provide a reliable way to package tablets and capsules. The clear blister allows for easy visibility, ensuring that consumers can see the product. This packaging also enhances product safety and extends shelf life.

In the food industry, blister packs protect items like cheese slices and snacks. They keep the products fresh and hygienic. Consumers appreciate the convenience of opening a single portion at a time. However, it's essential to consider the environmental impact. Many blister packs are not recyclable.

Tips for success include selecting the right material for your specific needs. Materials should be compatible with the product being packed. Test your designs to find the best fit. Moreover, consider the automation level of your packing line. Automation can improve efficiency but may require a higher initial investment. Remember, careful planning saves time and reduces waste in the long run.

Cost-Effectiveness of Blister Packaging Solutions for Businesses

Blister packaging offers a practical solution for many businesses. It minimizes waste and optimizes material usage. This form of packaging is not only efficient; it is also cost-effective. By reducing the chance of product damage during transport, companies can save on unexpected losses. Fewer returns mean increased customer satisfaction and loyalty.

Investing in blister packing machines can be beneficial. These machines automate the packaging process, cutting labor costs. They’re versatile and can handle different product sizes and materials. However, the initial investment can be daunting for small businesses. It requires careful financial planning and consideration.

Moreover, the trade-off of using blister packaging includes environmental concerns. While it saves money, the materials may impact sustainability efforts. Companies need to think about recyclable options. Balancing cost and environmental responsibility can be challenging but is essential in today's market. By evaluating both immediate returns and long-term sustainability, businesses can make informed packaging decisions.

Related Posts

-

Exploring Innovative Alternatives to the Traditional Blister Packing Machine

-

How to Select the Right Blister Packing Machine for Your Production Needs

-

Exploring the Benefits of Using an Automatic Blister Packing Machine in Modern Manufacturing

-

7 Best Strategies to Optimize Your Blister Machine Investment

-

Exploring the Benefits of Vacuum Formed Trays in Modern Packaging Solutions

-

Why Choose Stock Blister Packaging for Your Product Needs