2025 How to Choose the Best Small Clamshell Packaging for Your Products

In the ever-evolving landscape of product packaging, the choice of packaging can significantly influence consumer perception and sales performance. As more businesses turn towards sustainability and functionality, "small clamshell packaging" has emerged as a favored option for many industries, including food, cosmetics, and retail. Renowned packaging expert, Dr. Emily Carter, emphasizes the importance of this choice, stating, "Selecting the right packaging is not just a matter of aesthetics; it defines how your brand connects with customers and how your products perform in the market."

Navigating the variety of small clamshell packaging options available can be daunting, especially for small businesses looking to make a big impact. This type of packaging offers numerous advantages such as versatility, visibility, and protective qualities, all while highlighting the product's features. As brands strive to create memorable unboxing experiences, understanding the different shapes, sizes, and materials of small clamshell packaging becomes vital.

In this guide, we will explore essential factors to consider when choosing the best small clamshell packaging for your products, including environmental considerations, functionality, and design appeal. By making informed decisions about your packaging, you can enhance your product's attractiveness and ultimately boost your brand's success in a competitive market.

Understanding the Basics of Small Clamshell Packaging

Small clamshell packaging has become an essential choice for many businesses looking to present their products attractively while ensuring protection. Understanding the basics of small clamshell packaging is crucial for making an informed decision. This type of packaging typically consists of a two-part shell that opens and closes like a clamshell, offering an excellent view of the product inside. It is popular in various industries, including food, cosmetics, and electronics, providing durability and convenience for consumers.

When selecting the right clamshell packaging for your products, consider the material used. Most clamshells are made from clear plastics, allowing for transparency and visibility, which can enhance product appeal on retail shelves. Additionally, think about the size and shape of your product to ensure a snug fit, minimizing movement during shipping.

**Tips:** Always prioritize eco-friendly materials if possible, as this can resonate with environmentally conscious consumers. Furthermore, evaluate the security features of the clamshell design; a reliable locking mechanism will prevent accidental openings. Lastly, consider adding custom inserts or compartments to keep your products organized and visually appealing within the clamshell.

2025 Small Clamshell Packaging Preferences

This bar chart illustrates the preference ratings of various aspects of small clamshell packaging for the year 2025. Key dimensions include material quality, transparency, cost efficiency, customization, size variety, and sustainability.

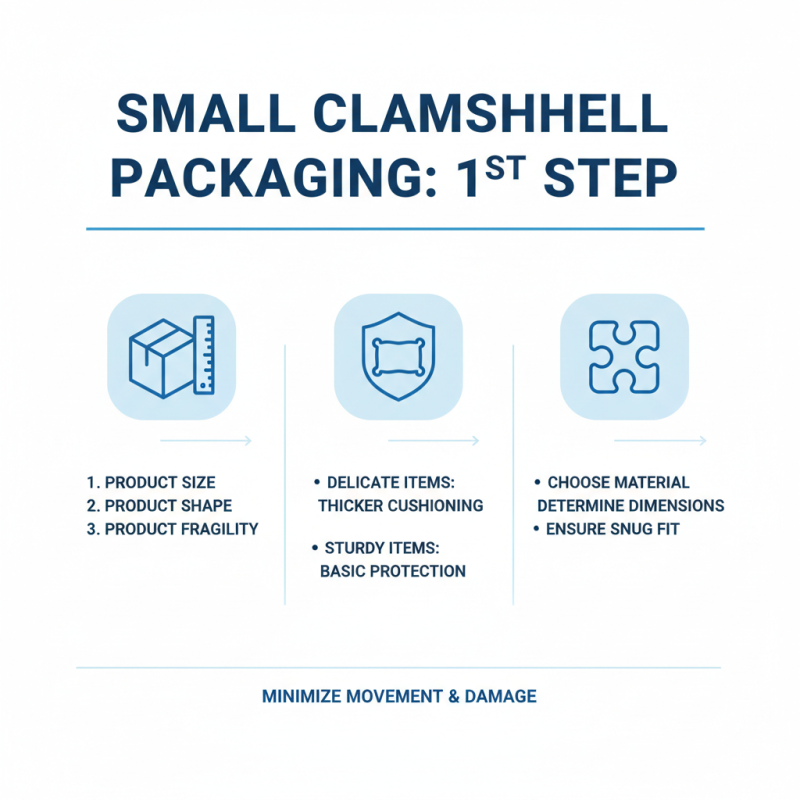

Identifying Your Product's Specific Packaging Needs

When selecting the best small clamshell packaging for your products, the first step is to identify your product's specific packaging needs. Consider the size, shape, and fragility of your product. For instance, delicate items may require thicker material or additional cushioning, while sturdy products might only need basic protection. Understanding these physical characteristics is crucial, as they will influence not only the type of clamshell material you choose but also its dimensions, ensuring a snug fit that minimizes movement and potential damage during transit.

In addition to the physical attributes, think about the visibility and presentation of your product. Clamshell packaging can serve as a marketing tool, so it’s important to consider how your product will be displayed within the packaging. Transparent clamshells allow customers to see the product clearly, which can enhance appeal. Moreover, consider whether your product is environmentally sensitive; opting for recyclable materials can not only meet consumer demand for sustainability but also align your brand with eco-friendly practices. Ultimately, assessing both the functional and aesthetic requirements of your product will lead you to the most suitable clamshell packaging solution.

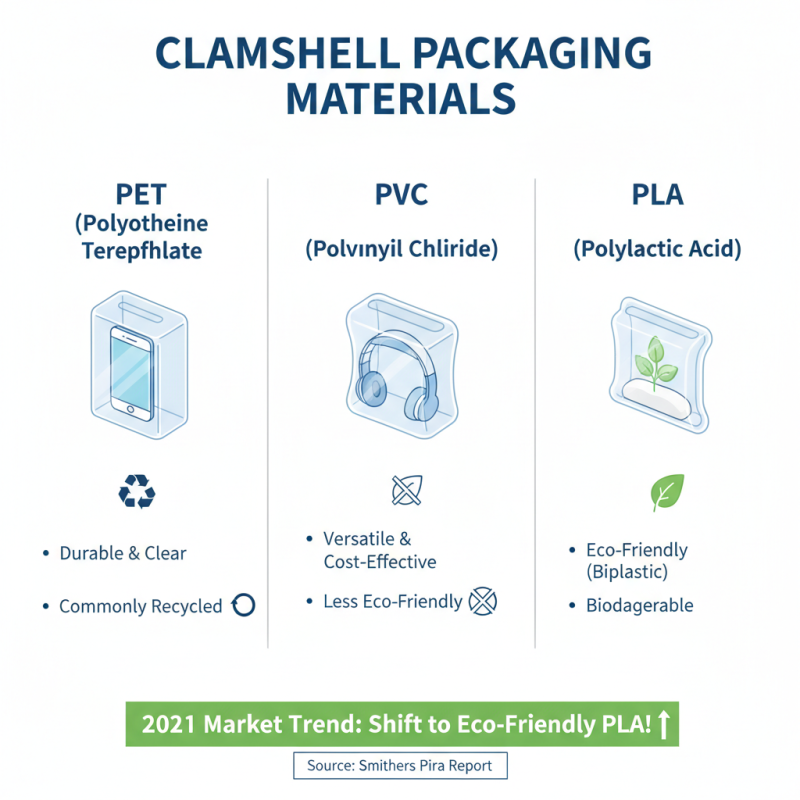

Evaluating Material Options for Clamshell Packaging

When selecting clamshell packaging, understanding the material options available is crucial for ensuring the durability and appeal of your products. Clamshells are primarily made from materials such as PET (Polyethylene Terephthalate), PVC (Polyvinyl Chloride), and PLA (Polylactic Acid). According to a 2021 market report by Smithers Pira, the demand for eco-friendly packaging solutions has led to a notable increase in the adoption of biodegradable materials like PLA. This bioplastic not only caters to sustainability-conscious consumers but also provides a comparable strength and clarity to traditional materials.

Additionally, the choice of material impacts not just the environmental footprint but also the overall usability and shelf life of the product. PET is favored for its excellent clarity and sturdiness, making it suitable for products that require visibility while ensuring protection. Data from the Flexible Packaging Association indicate that 65% of consumers prefer packaging that keeps products visibly fresh while remaining easy to open. In contrast, PVC, while less costly, may pose environmental concerns due to its long degradation period. Thus, brands must weigh the benefits of each material choice against sustainability goals and consumer preferences to determine the most effective clamshell packaging for their offerings.

Comparing Design Features and Aesthetic Appeal

When choosing the best small clamshell packaging for your products, comparing design features and aesthetic appeal is crucial. Clamshell packaging is not only functional but also plays a vital role in how consumers perceive your brand. A well-designed clamshell can enhance the visual appeal of your products, attracting potential buyers. Consider factors such as transparency, shape, and the overall emphasis on brand identity when selecting your packaging.

Tips: Focus on the clarity of the material used for clamshells. A transparent design allows customers to view the product inside, which can significantly influence their purchasing decision. Additionally, consider utilizing eco-friendly materials that speak to the consumers' growing demand for sustainable products. This not only showcases your commitment to the environment but also adds to the aesthetic appeal of your packaging.

Another essential aspect is the design's compatibility with your product. Ensure that the size, shape, and functionality of the clamshell enhance the product's presentation while providing adequate protection. Creative shapes and innovative closures can further elevate the aesthetic, making your product stand out on retail shelves. Remember, the right combination of design features and visual appeal can boost customer engagement and brand loyalty.

2025 How to Choose the Best Small Clamshell Packaging for Your Products - Comparing Design Features and Aesthetic Appeal

| Feature | Option 1 | Option 2 | Option 3 |

|---|---|---|---|

| Material Type | PET | PVC | PLA |

| Thickness (mm) | 0.5 | 0.75 | 1.0 |

| Transparency | Clear | Frosted | Colored |

| Seal Type | Heat Seal | Pressure Seal | Peg Seal |

| Eco-Friendliness | Recyclable | Non-Recyclable | Compostable |

| Printability | High Quality | Standard | Minimal |

Assessing Cost-Effectiveness and Environmental Impact

When considering small clamshell packaging for your products, assessing cost-effectiveness and environmental impact is crucial. The choice of material can significantly influence both the financial aspect and sustainability of the product. For instance, opting for biodegradable materials may incur higher upfront costs compared to traditional plastic, but they often lead to long-term savings by appealing to a growing market of environmentally conscious consumers. Furthermore, incorporating recycled materials can reduce production costs while minimizing the carbon footprint, aligning business practices with sustainable development goals.

In addition to material selection, the design of the clamshell packaging plays a vital role in maximizing cost-effectiveness. Efficient use of space can reduce shipping costs by allowing for greater quantities to be transported at once. Additionally, innovative designs that facilitate easy opening and resealing can enhance user experience, potentially leading to increased customer loyalty and repeat purchases. Balancing these factors—cost, material choice, and design—helps businesses make informed decisions that support both profitability and environmental responsibility.

Related Posts

-

How to Choose the Right Clear Clamshell Packaging for Your Products

-

Maximize Freshness and Convenience with Innovative Bulk Clamshell Packaging Solutions

-

2025 Guide: How to Choose the Best Stock Clamshell Packaging for Your Products

-

10 Best Bulk Clamshell Packaging Solutions You Need to Consider for Your Business

-

Essential Checklist for Choosing the Right Plastic Clamshells for Your Products

-

Exploring Market Trends for Stock Clamshells at the 138th Canton Fair in 2025