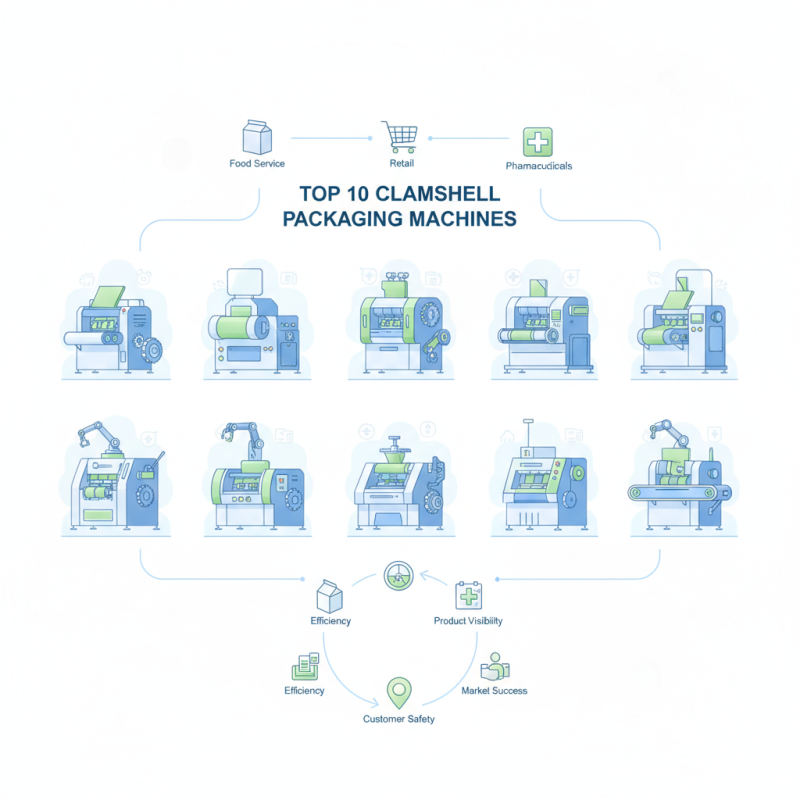

Top 10 Clamshell Packaging Machines: Best Options for Your Business Needs

In the fast-evolving landscape of packaging solutions, the importance of selecting the right machinery cannot be overstated. Clamshell packaging machines have emerged as a pivotal component for businesses aiming to enhance both product visibility and customer safety. According to packaging industry expert John Smith, “The efficiency and versatility offered by clamshell packaging machines make them an invaluable asset for companies looking to streamline their packaging processes.” This sentiment echoes the growing trend among manufacturers and retailers who are turning to this packaging solution for its practicality and aesthetic appeal.

As we delve into the top ten clamshell packaging machines, it’s essential to understand the diverse needs of various industries. Whether you operate in food service, retail, or pharmaceuticals, the right clamshell packaging machine can significantly influence your operational efficiency and produce a lasting impression on consumers. By exploring the best options available, businesses can make informed decisions that align with their product requirements and market strategies, ultimately driving success in a competitive marketplace.

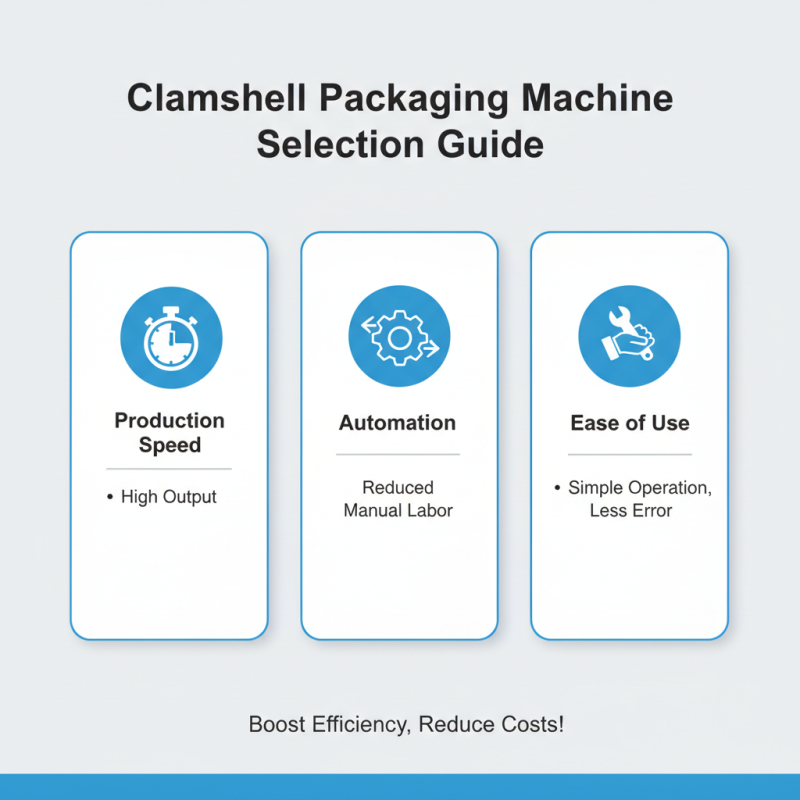

Top Features to Consider in Clamshell Packaging Machines

When selecting a clamshell packaging machine for your business, several key features should be evaluated to ensure it meets your operational needs. The machine’s production speed is crucial, as a faster output can significantly enhance overall efficiency in a high-demand environment. Additionally, the ease of use and automation features are essential; machines that require less manual intervention can save time and reduce the likelihood of errors during packaging.

Another important aspect to consider is the machine’s versatility in handling various product sizes and shapes. A flexible clamshell packaging machine allows for adjustments and adaptations, making it easier to accommodate new products as your business grows. Furthermore, pay attention to the machine’s construction and material quality, as these factors impact durability and maintenance costs over time. Investing in a reliable machine will lead to lower downtime and enhance productivity in the long run.

Industry Trends in Clamshell Packaging: Demand and Growth Insights

The clamshell packaging market has seen significant growth in recent years, driven by a surge in consumer demand for convenience and sustainability. According to a recent market research report, the global clamshell packaging market is projected to grow at a CAGR of 5.4% from 2021 to 2028. This expansion is attributed to the increasing use of clamshells in food packaging, retail, and electronics due to their protective features and eye-catching designs. The trend towards eco-friendly materials has also prompted manufacturers to innovate in biodegradable and recyclable options, aligning with consumer preferences for sustainable products.

As businesses consider clamshell packaging solutions, there are a few essential tips to keep in mind. First, evaluate the specific needs of your product—size, weight, and fragility—as these factors will influence the choice of materials and design. Second, stay updated on industry regulations regarding packaging materials, as compliance can significantly impact your brand's reputation and operational efficiency. Lastly, consider incorporating transparent designs that enhance visibility and product appeal to consumers, as studies show that packaging visibility can lead to increased sales.

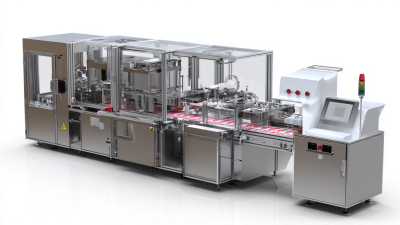

The ongoing demand for clamshell packaging is also shaped by technological advancements in machinery that enhance design versatility and production efficiency. Companies are increasingly investing in smarter machinery that allows for customization and quicker turnaround times, which, according to industry experts, is crucial for keeping up with the fast-paced market dynamics. Adapting to these trends not only meets consumer expectations but also positions businesses favorably in a competitive landscape.

Comparison of Speed and Efficiency Metrics in Clamshell Machines

When selecting a clamshell packaging machine, it’s crucial to focus on speed and efficiency metrics, which are often the primary drivers of productivity in manufacturing. Industry reports indicate that the average speed of clamshell machines can range from 30 to 120 cycles per minute, depending on the design and technology integrated into the machine. A recent analysis highlighted that machines with advanced automation features can achieve up to 50% higher operational efficiency, crucial for businesses looking to scale production without compromising quality.

To maximize the benefits of clamshell packaging, consider investing in machines equipped with energy-efficient motors and quick-change capabilities. These features not only improve productivity but also reduce downtime during product changeovers. Additionally, monitoring the machine's performance metrics, such as cycle times and error rates, can provide valuable insights for ongoing improvements. Regular maintenance checks are essential; reports suggest that proactive maintenance can increase machine lifespan by up to 20%, translating to significant cost savings over time.

Tips: Always evaluate your production needs against the speed capabilities of the machine. If high volumes are anticipated, prioritize models that offer modular components for easy upgrades. Furthermore, conduct thorough benchmarking studies with your current equipment to identify performance gaps that newer machines could address effectively.

Top 10 Clamshell Packaging Machines: Speed and Efficiency Comparison

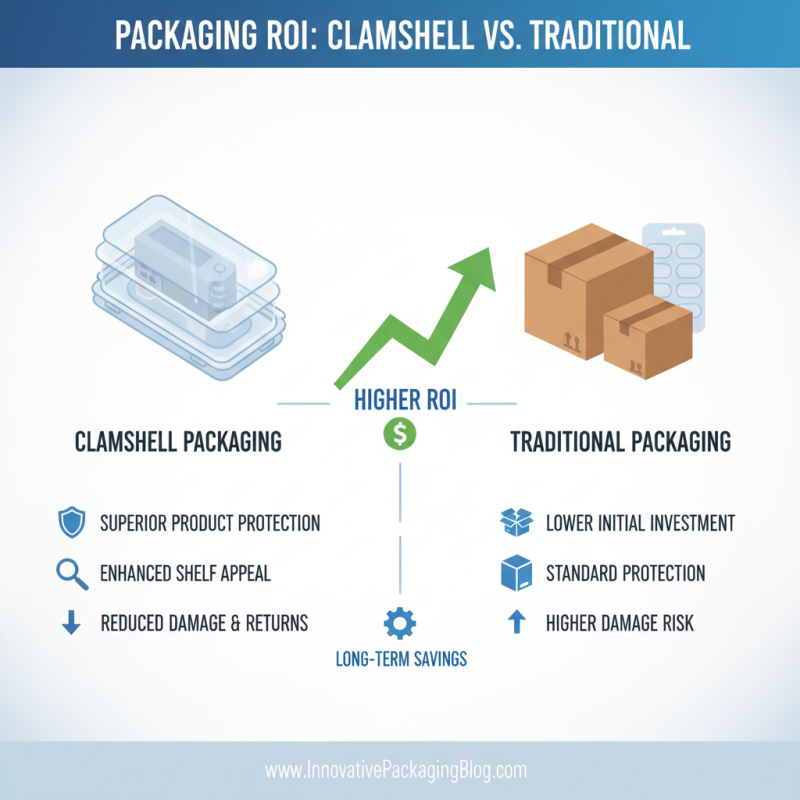

Cost Analysis: ROI of Clamshell Packaging Versus Traditional Methods

Clamshell packaging has gained popularity due to its versatility and protection it offers to products. When comparing the ROI of clamshell packaging to traditional methods, businesses often find significant benefits. Although the initial investment for clamshell packaging machines may be higher, they provide a sturdy and visually appealing solution that can enhance the shelf presence of products. Additionally, clamshell packaging reduces product damage during transportation, minimizing costs associated with returns and replacements.

**Tip:** To maximize your ROI, consider integrating a clamshell packaging machine that offers automated features. Automation reduces labor costs over time and increases efficiency, allowing your team to focus on other critical tasks.

Moreover, clamshells are often more sustainable when designed for recyclability, appealing to environmentally conscious consumers. This shift can lead to increased sales, as more businesses align with eco-friendly practices. Analyzing the long-term savings from reduced materials and better product security can significantly influence your decision-making process.

**Tip:** When assessing the cost-effectiveness of clamshells versus traditional methods, run a pilot program. This will help you gather real data on operational efficiency and customer feedback, making the financial analysis more accurate.

Sustainability in Clamshell Packaging: Innovations and Eco-Friendly Options

Sustainability is becoming a pivotal consideration in the packaging industry, prompting businesses to seek clamshell packaging solutions that align with eco-friendly practices. Innovations in materials, such as the development of biodegradable and compostable plastics, are helping reduce the environmental footprint associated with traditional clamshell packaging. By choosing sustainable materials, companies can not only minimize waste but also appeal to a growing consumer base that prioritizes environmental responsibility.

When exploring clamshell packaging options, businesses should consider the recyclability of their chosen materials. Opting for products that are easily recyclable can enhance a company's sustainability profile while contributing to a circular economy. Additionally, investing in machinery that is energy-efficient can further support eco-friendly practices, ensuring that your production processes are as sustainable as your packaging choices.

Tips: To maximize sustainability in clamshell packaging, always keep an eye on emerging technologies that promote eco-friendliness. Evaluate your supply chain to source materials from reputable providers who adhere to sustainable practices. Lastly, educate your customers about the recyclability of your packaging and encourage responsible disposal to foster a community focused on sustainability.

Related Posts

-

Understanding the Benefits of Clamshell Packaging Machines for Eco-Friendly Product Solutions

-

Addressing Challenges in Clam Packaging for Optimal Product Preservation

-

Essential Checklist for Choosing the Right Plastic Clamshells for Your Products

-

The Rising Demand for Plastic Clamshell Packaging in Sustainable Retail Solutions

-

How to Choose the Best Plastic Clamshell Containers for Your Packaging Needs

-

10 Best Bulk Clamshell Packaging Solutions You Need to Consider for Your Business