2026 Top Packaging Sealing Machines You Need to Know?

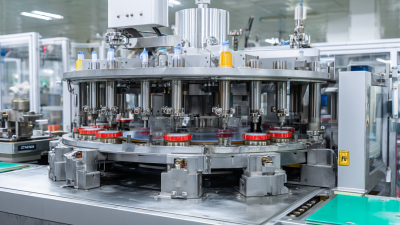

In the fast-evolving world of packaging, the significance of an efficient packaging sealing machine cannot be overstated. These machines ensure products remain fresh, secure, and appealing. In 2026, a diverse range of sealing machines is set to redefine productivity and design in the packaging industry.

Sealing technology continues to advance, with various options available. Brands are focusing on user-friendly machines that enhance speed and reliability. Innovations in materials and processes could lead to more sustainable packaging solutions. As we explore this topic, it's essential to acknowledge that even the best machines have limitations.

Challenges with maintenance and compatibility remain, requiring ongoing adaptation. Users may struggle to find the right fit for their specific needs. Understanding the strengths and weaknesses of each packaging sealing machine is crucial for making informed decisions. This landscape promises excitement and requires careful consideration to navigate effectively.

2026 Key Trends in Packaging Sealing Machines Industry

The packaging sealing machines industry is undergoing significant changes in 2026. Automation is becoming essential. Many businesses are integrating robots for efficiency. This shift cuts labor costs and speeds up production. There's a growing focus on sustainability as well. More companies are opting for eco-friendly materials. However, this transition requires careful planning and investment.

Data analytics is also playing a critical role. Companies are using big data to optimize their sealing processes. This allows for real-time adjustments and more effective operations. Yet, relying too much on technology can lead to unexpected challenges. Training staff to adapt to new systems is crucial. Innovation brings potential, but also a need for continuous learning.

Another key trend is customization. Customers want unique packaging solutions. Companies are responding by offering tailored sealing options. This can boost customer satisfaction but can also complicate production lines. Striking a balance between flexibility and efficiency is vital. As the industry evolves, there's much to consider. Engaging with these trends can lead to success, but it also requires reflection on current practices.

2026 Top Packaging Sealing Machines You Need to Know

| Machine Type | Sealing Method | Speed (Packages/min) | Power (kW) | Application |

|---|---|---|---|---|

| Horizontal Flow Wrapper | Heat Sealing | 120 | 2.5 | Snacks & Confectionery |

| Vertical Form Fill Seal | Cold Sealing | 80 | 1.8 | Beverages & Liquids |

| Cup Sealing Machine | Pressure Sealing | 60 | 1.0 | Dairy Products |

| Pouch Sealer | Impulse Sealing | 150 | 2.0 | Ready-to-Eat Meals |

| Band Sealer | Continuous Sealing | 100 | 3.0 | Granules & Powders |

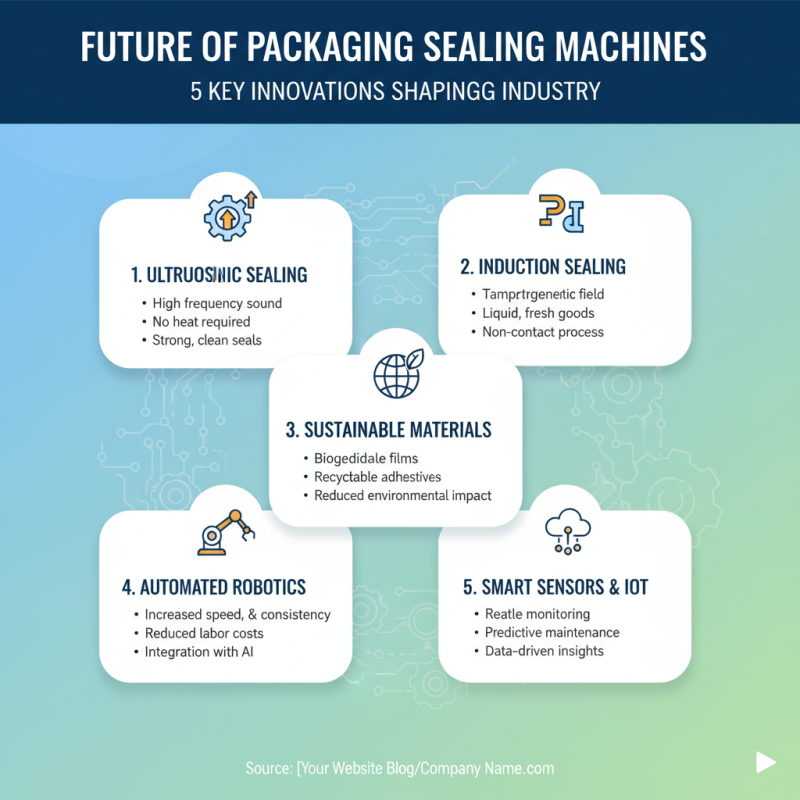

Top Five Technologies Revolutionizing Packaging Sealing Machines

The packaging industry is experiencing a significant transformation thanks to new technologies. Here are five key innovations in packaging sealing machines that are shaping the future.

Heat sealing technology has shown promising growth. Reports indicate that the global heat-sealing machine market is projected to reach $2.2 billion by 2026. This method ensures efficient sealing for flexible materials. It’s faster and often more cost-effective, appealing to many manufacturers.

Another groundbreaking technology is ultrasonic sealing, which minimizes material stress. This process uses high-frequency sound waves to generate heat. Studies show that ultrasonic sealing can reduce energy consumption by up to 30%. This reduction could lead to substantial cost savings for companies.

Automated systems are also making waves. With Industry 4.0 on the rise, smart packaging machines are becoming crucial. They offer real-time data analysis and monitoring. Companies can react promptly to issues, improving overall efficiency.

Tip: When choosing a sealing machine, consider energy use and output quality. Machines that save energy aren’t just eco-friendly; they can be cost-efficient too.

Advancements like laser sealing are being explored but may still pose challenges. Ensuring a reliable seal with varying materials can be complex. Testing new technologies in real-world settings is essential for success. Adaptability will be key in this evolving landscape.

Market Analysis: Growth Projections for Packaging Sealing Machine Segment

The packaging sealing machine segment continues to surge. Industry reports project growth rates of approximately 7% annually through 2026. This increase is fueled by rising demand across sectors, like food, pharmaceuticals, and consumer goods. Efficient sealing solutions are critical to ensure product safety and extend shelf life.

Data from market analyses indicate that technological advancements play a significant role. Automation and smart features enhance productivity and accuracy. However, some enterprises struggle to adopt these new technologies. This gap can hinder potential growth. There’s a need for training and adaptation to fully leverage these innovations.

Sustainability is another factor driving this segment. Consumers increasingly prefer eco-friendly packaging. This shift urges manufacturers to consider sustainable materials in sealing solutions. Still, many face challenges in sourcing eco-friendly options. While the growth trajectory appears positive, addressing such obstacles is crucial for long-term success.

Comparative Review of Leading Packaging Sealing Machine Brands in 2026

In 2026, the landscape of packaging sealing machines shows significant advancements. A recent report indicates that the global market is projected to grow at a CAGR of 4.5%, driven by increasing demand across various industries. Companies are focusing on automation and efficiency to meet consumer needs. However, a mismatch between technology and user skills presents a challenge. Employees must adapt to new systems rapidly.

Leading brands emphasize the importance of energy efficiency and sustainability. About 30% of companies are investing in eco-friendly materials for their machines. This shift not only meets regulatory demands but also attracts environmentally conscious consumers. Yet, the transition can lead to production downtime, sparks concerns about investment returns.

Moreover, user feedback reveals a consistent need for better support and training. Roughly 25% of operators feel inadequately trained on new machines. This gap can hinder productivity and efficiency. Industry leaders must prioritize comprehensive training programs. Overcoming these obstacles will define success in the evolving market of packaging sealing machines in 2026.

2026 Top Packaging Sealing Machines Performance Comparison

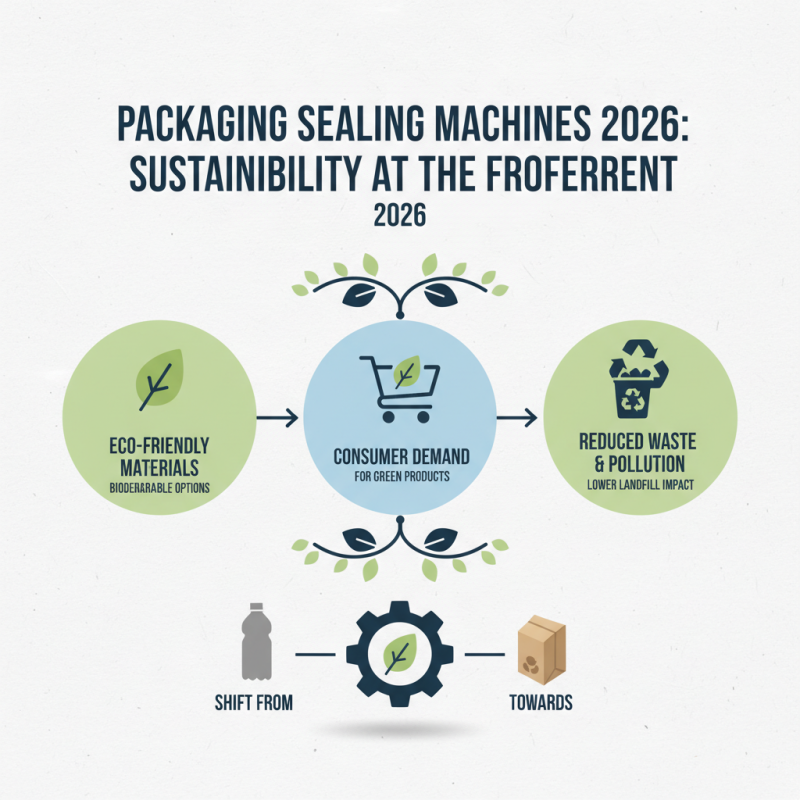

Sustainability Innovations in Packaging Sealing Machines for 2026

As we head into 2026, sustainability in packaging sealing machines takes center stage. Manufacturers are focusing on eco-friendly materials. This shift is driven by increasing consumer demand for environmentally sound products. It is increasingly clear that traditional materials create excess waste and pollution. A growing number of companies are exploring biodegradable options. These materials break down more easily, reducing landfill impact.

Energy efficiency is another key area of innovation. New machines aim to minimize energy consumption during the sealing process. While progress is evident, some machines still fall short of industry standards. It’s crucial to develop machines that not only seal effectively but also conserve resources. Moreover, smart technology integration is becoming common. However, the initial costs remain high, which can be a barrier for many small manufacturers.

Additionally, there is a trend towards recyclable packaging designs. Companies are rethinking how to package their products. Many are now designing packages that can be reused after opening. This approach encourages consumers to think sustainably. However, not all designs are effectively communicating this message. As businesses innovate, they must also ensure that their sustainability claims are genuine. Addressing these imperfections can enhance credibility and consumer trust.

Related Posts

-

Top 10 Benefits of Using a Packaging Sealing Machine for Your Business

-

What is an Automatic Blister Packing Machine and How Does It Work

-

2025 Guide: How to Choose the Best Tray Sealer for Your Business Needs

-

Exploring the Benefits of Blister Card Packaging for Eco-Friendly Product Marketing

-

Revolutionizing Product Safety: The Rise of Eco-Friendly Blister Packaging Materials in 2023

-

Exploring the Benefits of Using an Automatic Blister Packing Machine in Modern Manufacturing